Recent Posts

- » New Combi Tank for 4 Pipe and DHW Preheat Applications

- » DX2W-EX3 now includes support for Radiant Cooling, Biomass Boilers and Solar Heating

- » DX2W-3 Release offers Native Support for Cold Climate Inverters

- » Installation Highlight: Using two heat pumps in tandem in mid-sized project in Dartmouth, NS

- » ThermAtlantic Pioneers Hydronic Cascading Heat Pumps for DHW Production

ThermAtlantic Pioneers Hydronic Cascading Heat Pumps for DHW Production

Posted by Benoit Maneckjee on 25th Mar 2024

In the fall of 2019 we started the installation of our first Hydronic Cascading Heat Pump installation for domestic hot water production at Stephenville Manor, a 128 unit apartment building in Stephenville, NL. This building had an outdated electric resistance based system which needed to be completely replaced so with the help of Newfoundland Power's Take Charge program the owners decided to invest in our heat pump cascade solution.

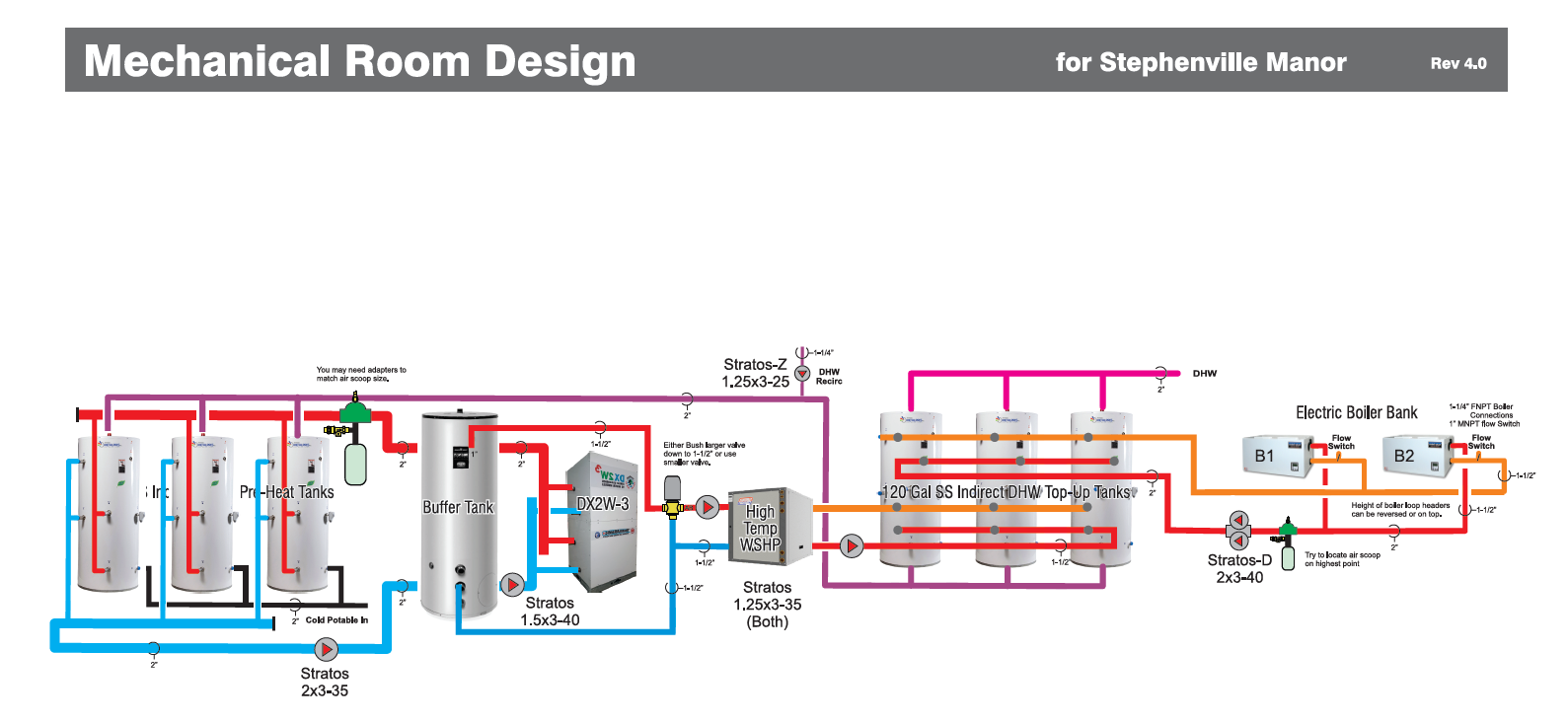

Mechanical illustration of the mechanical room. (doesn't show 4 heat pumps outside)

Our design uses four 5 ton Goodman air source heat pumps connected to one of our 20 ton 4 pipe DX2W-3 modules to heat a 200 gal buffer tank to a target temperature of 100-115°F all year round. This tank first pre-heats three 120 gal indirect tanks filled with potable water between 90-110°F. This pre-heated DHW is then fed into three more indirect tanks with double coils and a 5 ton high temp water source heat pump is used to boost the DHW to a target temperature of 125-135° using the lower coils. The WSHP uses the same 200 gal buffer tank water to run through its evaporator so that it can produce the 135-145°F water temperatures needed to raise the DHW. Two 42 kW electric boilers are used for backup and supplementary heat and are connected to the top coils of the three top-up tanks in the event that the heat pumps can't meet the DHW demand in a timely fashion.

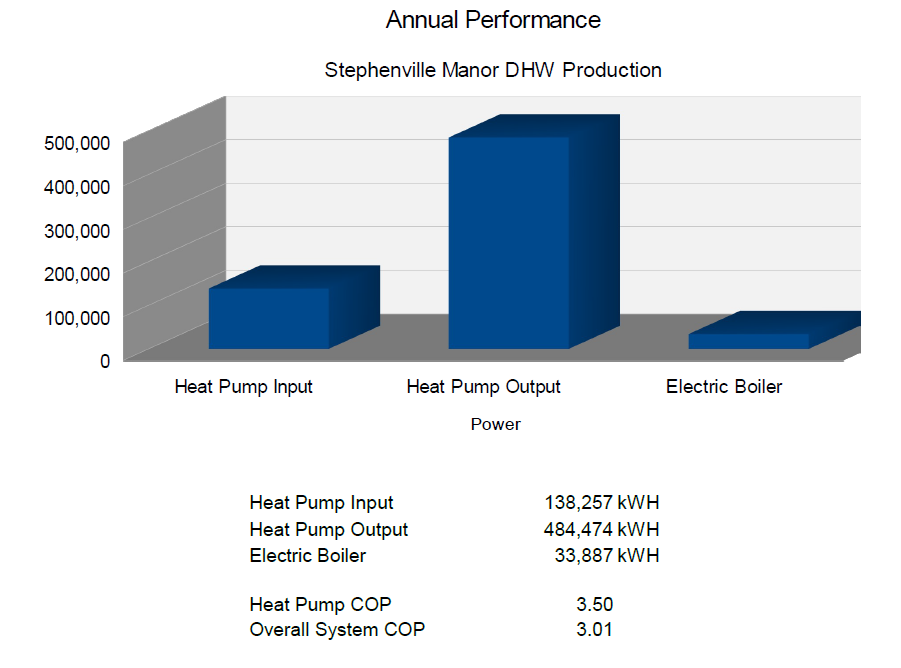

The entire installation was plumbed by Quality Mechanical and is connected to our cloud-based monitoring service so that we could optimize performance, detect problems, diagnose them and record historical performance. The system was started-up on March 5th, 2020 and after it's first year we were able to determine it's annual performance as summarized below:

The Graph shows energy use and annual performance after the first year.

Photo showing he 4 x 5 ton residential heat pumps outside

Photo showing 20 ton DX2W-3 module connecred to 200 gal buffer tank inside and linesets going to 4 heat pumps.

Photo showing 3 of our dual coil indirect 120 gal tanks used for DHW pre-heat using buffer tank as heat source.

Photo showing High-Temp R-134A WSHP used to boost preheated water to 130°F using bottom coils of 3 more indirect tanks used to store DHW. Note that WSHP uses same buffer tank as preheat as the evaporative source.

Photo showing two 42 kW electric boilers for redundant backup. These are piped to the top coils of the DHW indirect tanks and only called-upon when needed.

Photo showing the control panel which is connectred to the internet via one of our IOT Pro gateways.

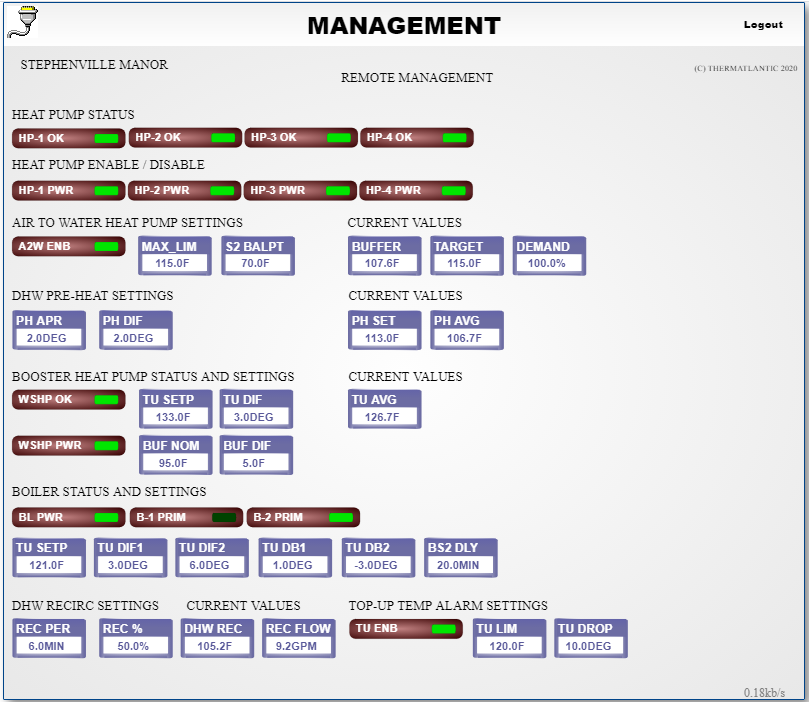

One of the things that makes a ThermAtlantic solution unique is that we include all the automation in our price and offer internet access and remote support on a modest annual fee based basis.

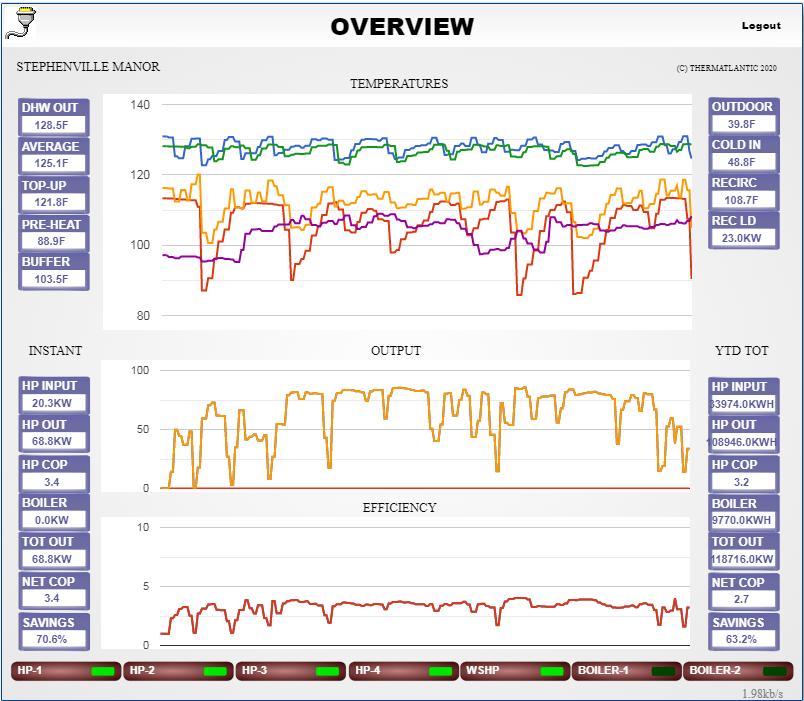

Web Dashboard showing real-time and historical performance

Web Dashboard used for remote management of the mechanical systems

Anyone interested in learning more about building a DHW hydronic cascade is welcome to contact us by phone or email.

Loading... Please wait...

Loading... Please wait...